Furniture Acrylic Tape Edge Banding Trimming Woodworking Machinery

(ET-60E)

(ET-60E)

1. Brief Introduction:

1) Semi-automatic edge sealing machine is suitable for the straight edge of the workpiece such as density plate, ecological board, fiber board, solid board, and particle board

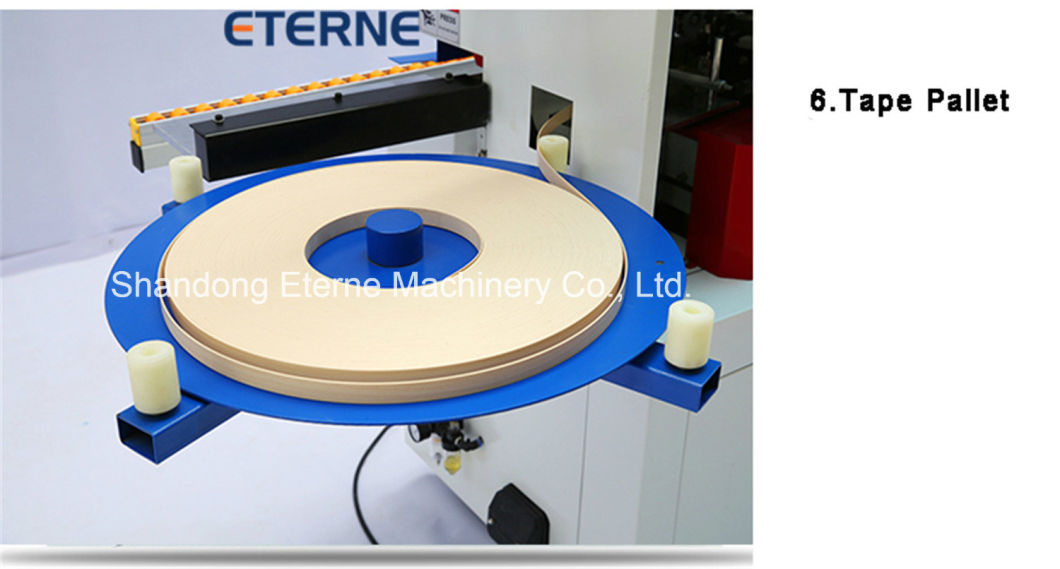

2) Banding edge for desks,carbinet,wardrobe and stright line furniture.The sealing material can be used for solid wood strips, PVC, Melamine and Bomupi.

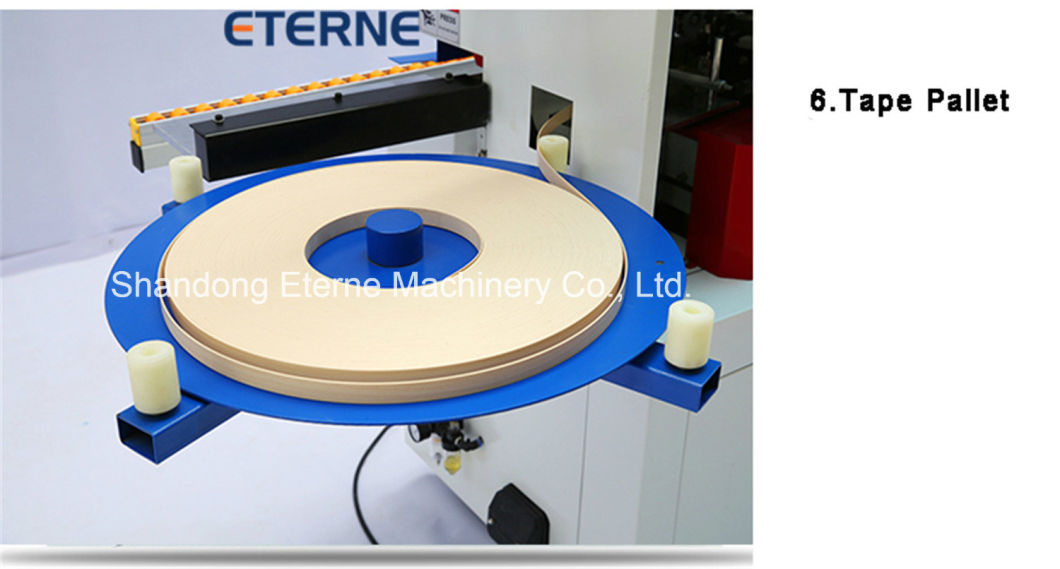

3) Tape material can be PVC,melamine, veneer etc.

4) Seal the back plate slot at one time to save labor, high precision and high efficiency.especially suitable for suitable for medium and large scale users.

5) Adopt imported motor and high quality electrical components.

2. Advantage:

1) The control screen adopts the Delisi control system, the button-type operation panel, and the operation is simple.

2) Automatic injection pump, no maintenance, can extend the service life of the machine.

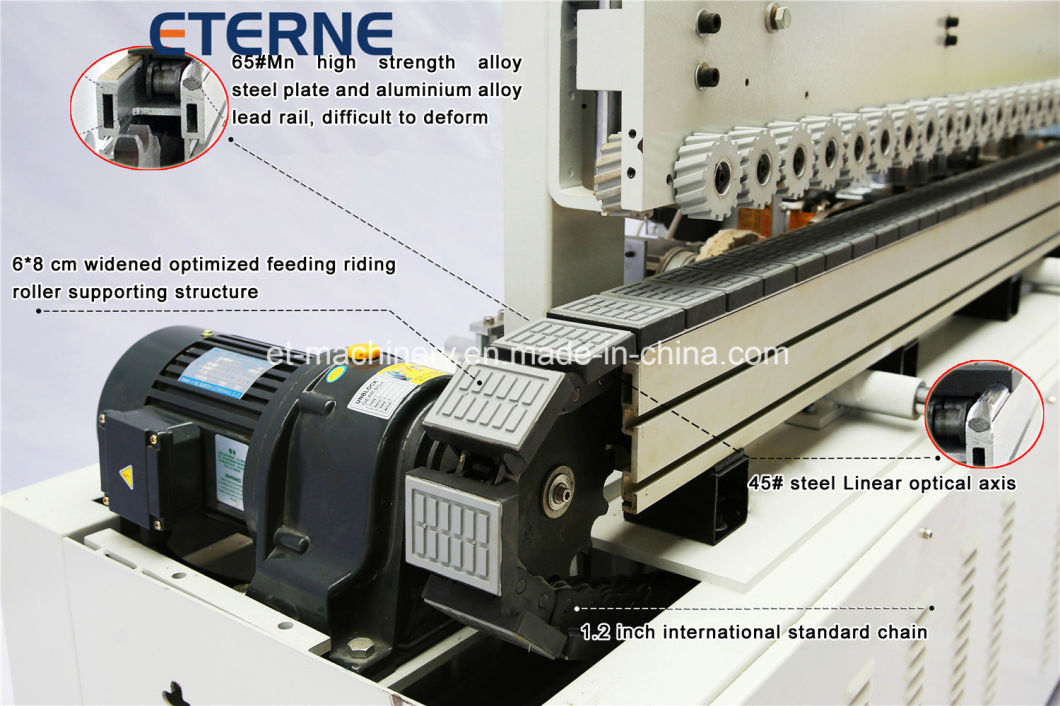

3) Aluminum alloy feed guide rail.

2) Automatic injection pump, no maintenance, can extend the service life of the machine.

3) Aluminum alloy feed guide rail.

3. Specification: ( can be customized)

| Model | ET-60 | ET-60E |

| Input Voltage | 380V(220V,400V,415V,440V etc) | 380V(220V,400V,415V,440V etc) |

| Edge Thickness | 0.4-3 mm | 0.4-3 mm |

| Edge Width | 12-55 mm | 12-55 mm |

| Panel Length | Min.120 mm | Min.120 mm |

| Panel Width | Min.60 mm | Min.60 mm |

| Panel Thickness | 10-50 mm | 10-50 mm |

| Feeding Speed | 12 m/min | 12 m/min |

| Transport Motor | 0.75 kw | 0.75 kw |

| Glue Post Motor | 0.37 kw | 0.37 kw |

| Fine-trimming Motor Power | 0.75 kw*2 | 0.75 kw*2 |

| Polishing Motor | 0.18 kw*2 | 0.18 kw*2 |

| Glue Box Heater | 1.5 kw | 1.5 kw |

| Work Pressures | 0.7 Mpa | 0.7 Mpa |

| Total Power | 4.0 kw | 4.0 kw |

| Buffing | without | With |

| Dimension | 2370/680/1460 mm | 2770 /680/1460 mm |

| Weight | 500 kg | 550 kg |

4.Features :

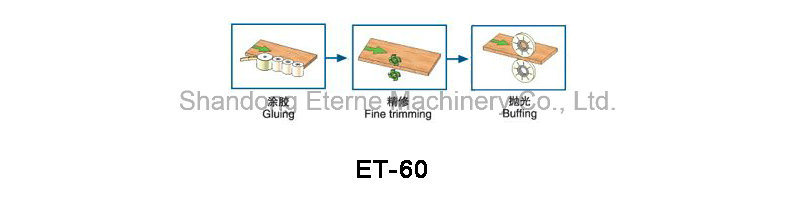

1) Multi-Fuction: Linear edge banding machine with gluing--end trimming--fine trimming--buffing.

1) Multi-Fuction: Linear edge banding machine with gluing--end trimming--fine trimming--buffing.

2) Gluing and press mechanism adopts glue melting device to gelatinize the plates and tape uniformly, meanwhile make sure they can be conglutinated firmly.

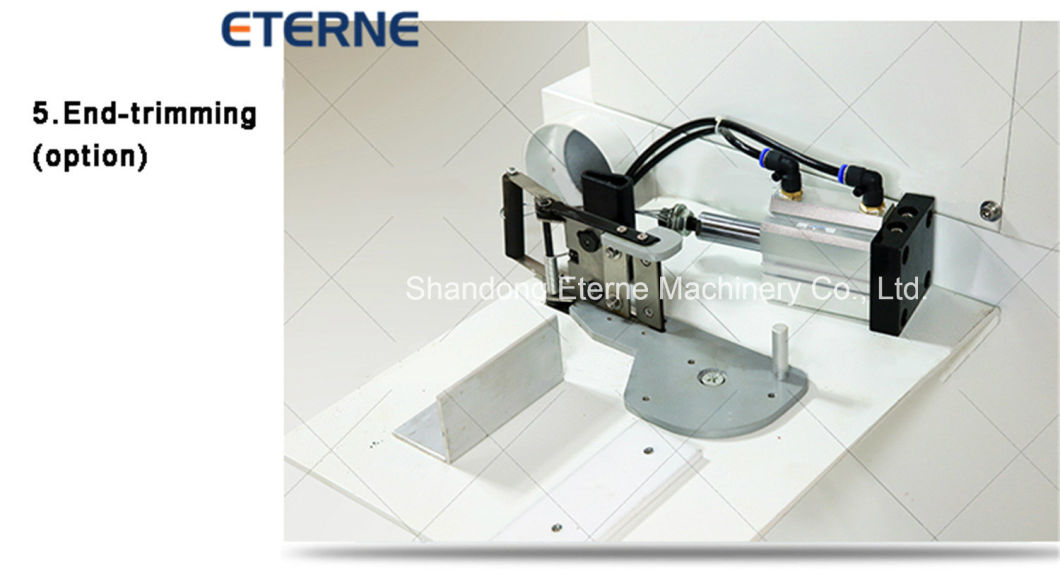

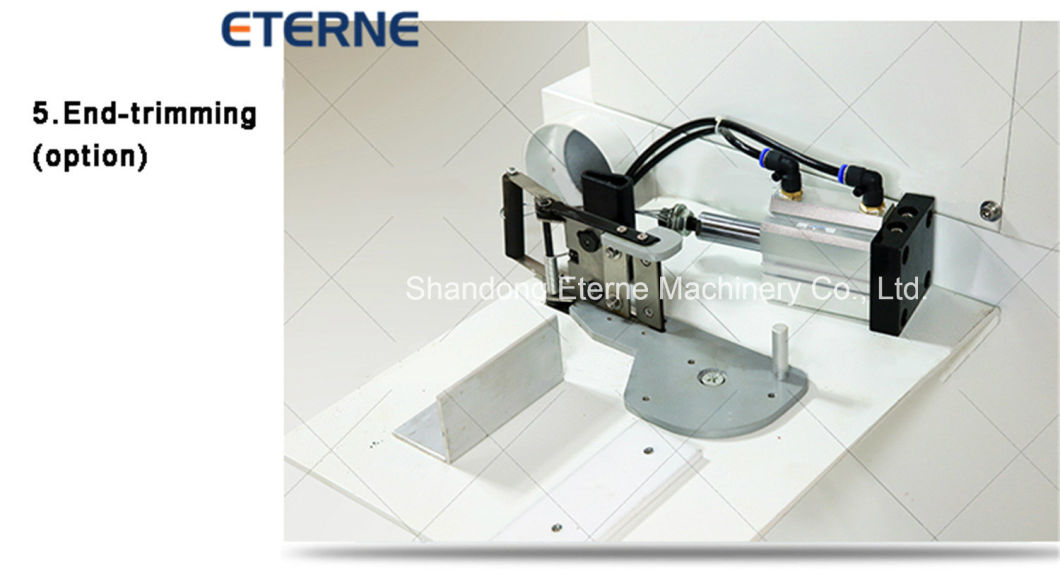

3) End-trimming mechanism is to cut the forward and rear tape after gluing and press process by the movement of the precise guide track, it is with automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.

4) Rough &Fine Trimming unit, with two individual high frequency motors, trim the exceeding edge on the top and bottom side of the panel, ensure both sides of the edge smooth and even.

5) Buffing unit is equipped with cotton polishing wheels to make smooth surface by end-polishing.

3) End-trimming mechanism is to cut the forward and rear tape after gluing and press process by the movement of the precise guide track, it is with automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.

4) Rough &Fine Trimming unit, with two individual high frequency motors, trim the exceeding edge on the top and bottom side of the panel, ensure both sides of the edge smooth and even.

5) Buffing unit is equipped with cotton polishing wheels to make smooth surface by end-polishing.

5. Pictures and details

6.Delivery and Package

1) No matter container shipping or LCL shipping, the machine will be packaged with standard plywood case and plastic flim rolling all around the machine for anti-dust.

2) Usually, If have machine in stock, it can deliver 2 days after deposit, if no, can be deliver within 7 days after deposit.

7. Why Choose Us

- Factory direct, with more than 10 years woodworking machinery production experience.

- Can do OEM/ODM according to your request.

- Engineer is available to help commissioning overseas.

- Within 24 hours response if any enquiry and quick after-sales service system.

- With own R&D strength .

Mis. Weiwei Su

MP:+86 15753429842

Thanks for your time and welcome to send enquiry.